One of the bigger issue with the motor was changing the FWC impeller without draining 1.5 gallons of anti-freeze as ONE time was ENOUGH

So i found i needed 1/2' ball valves and 3/8 X 1/2 male nipples as the 3/8 valves were just to small

I had to tweak one handle to tighten the valve But there is enough there to open and close the valves once or twice a year :)

The hatch is back from powder coating and looks great and the waterjet place should have the lens cut this week as i HATE cutting and sanding plastic

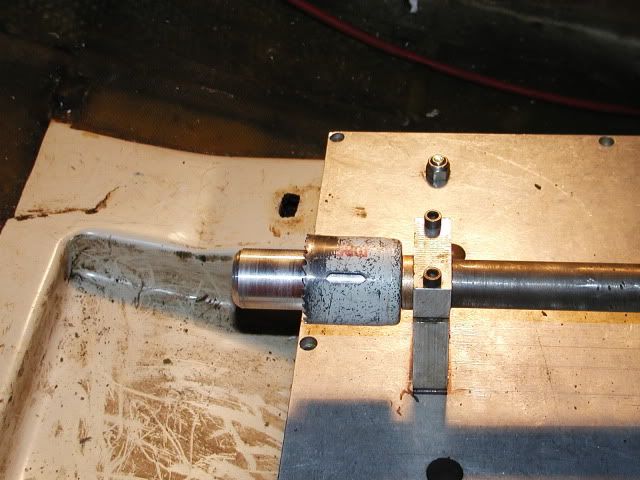

I made two seacock mounting plates using the great Mainsail guide at

http://www.pbase.com/mainecruising/boat_projects

And for the final touch i pumped out 15 gallons a REALLY bad gasoline and got the tank out of the boat and called it a day on Sunday as i do have to work a real job :)